In some industrial environments, premature chain failure occurs due to humidity, mildly acidic, alkaline, oily, high-density dusty, polluted gas, etc… conditions, coupled with high and low temperature operating environment. Long period exposing to such conditions cause unplanned machinery stoppage, to the extent of contaminating the manufactured products and equipment breakdown, interrupt operation and escalate cost.

As a result of extensive tests conducted, we have developed a series of environmental-resistant chains, that include stainless steel, galvanized, nickel-plated, Dacromet, phosphating, Super-Zinc, etc… widely used in textile, food, packaging, chemical, water-treatment, environmental protection, outdoor mechanical transmission, pharmaceutical, print and dye, electronics, dust treatment, and other fields.

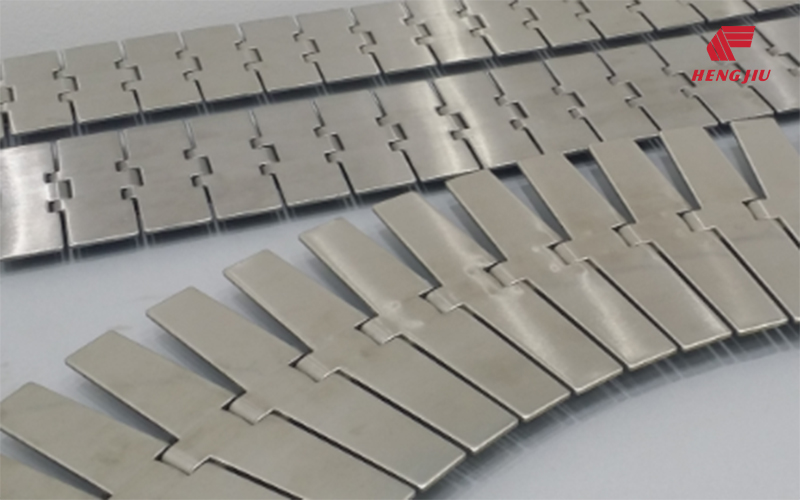

Stainless Steel ChainsStainless steel chain has the advantages in resisting acidic, alkaline, cold and hot temperature, and hygienic, widely used in food, pharmaceutical, chemical, print and dye, electronics, environmental protection and other industrial fields; a good mechanical chain transmission solution for high and low temperature operating environment.

According to different usage environments, every stage in the manufacturing process of the stainless-steel roller chain is closely monitored by the factory’s ISO9001 quality assurance system, resulting in high-quality and wide range of product, suitable for demanding environments for corrosion resistance, high and low temperature operation condition.

The sleeves and rollers of the stainless-steel roller chain are formed by cold extrusion; the side plates are cold-rolled and hardened through multi-step process. These processes ensure the tensile strength of our stainless-steel roller chain to achieve more than 25% above similar products by other brands.

In addition to stainless-steel short-pitch roller chains, we also provide large-pitch stainless-steel conveyor chains for applications such as wastewater treatment, and all stainless-steel parts undergo heat-treatment.

1. StainlessSteel Roller Chain The Company has more than 40 years of manufacturing experience in stainless-steel roller chain. Considering various working environment, our stainless-steel chains are made from SUS300 series stainless steel, every manufacturing process is strictly audit according to ISO9001 quality assurance system. These series of high quality and widely used products suits extreme working conditions. The company can also provide chains pre-lubricated with USDA-approved lubricants that meet food grade health standards .

All the bushes and rollers for our stainless-steel chains are formed using cold extrusion, and the side plates hardened through multi-step of cold rolling. With all these manufacturing techniques ensure the tensile strength of our stainless-steel roller chains exceeds 25% over that of similar products by other brands.

Chains with Galvanized, Nickel-Plated, Dacromet, PhosphatingLow-Maintenance Chain

In some operations and application environments wherever relubrication is impossible or undesirable on hygiene grounds. To meet these requirements, our low-maintenance chain is recommended solution. There are many features and benefits our low-maintenance chains can offer – O-rings, X-rings, sealed (pre-lubed) bearings, with lubrication ports and lubricators, and lube-free bushings.

Compared with ordinary chains, low-maintenance chains last longer. It leads to increased productivity for users, reduce maintenance frequency, less downtime enhance better machinery utilization, and reduce total cost.

Different working conditions require very different lubrication-free technologies. To effectively implement low-maintenance chains, the users shpuld consult a professional manufacturer. Hengjiu Group has accumulated vast expertise in applications in automated parking garage, metallurgy industry, automobile production line, cement production equipment, grain and oil machinery, food packaging, motorcycle, agricultural machinery, fitness equipment, beverage equipment, logistics processes, etc..., We look forward to advising and providing you with the suitable solution.

Plastic Chain & Belt