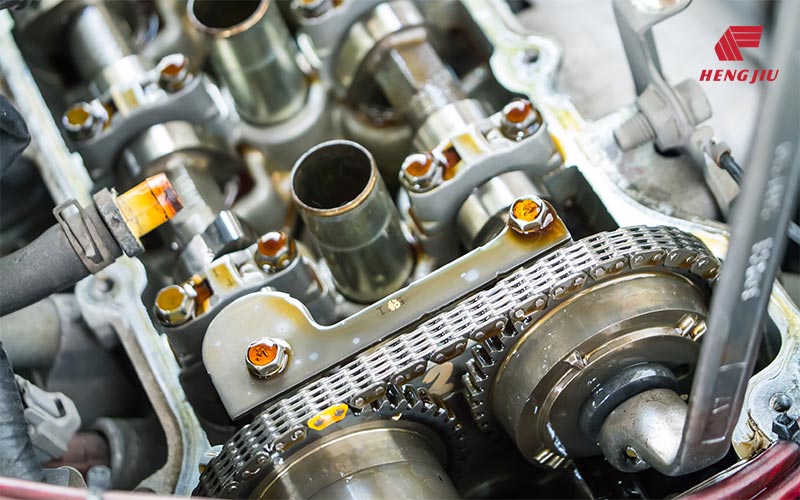

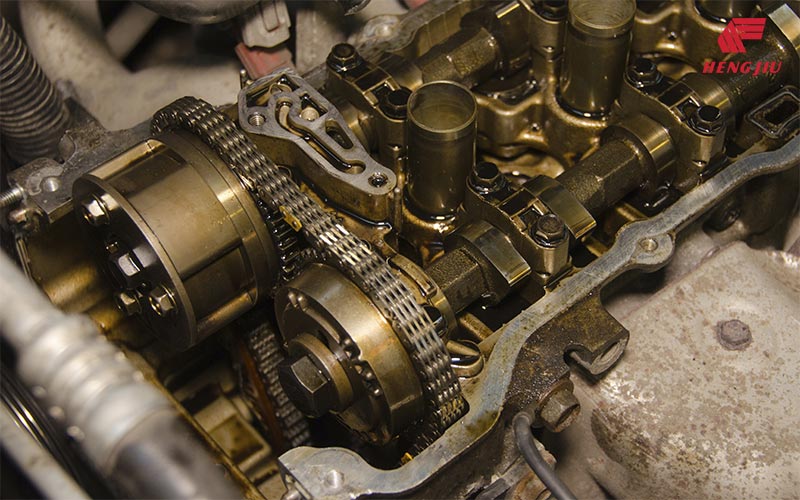

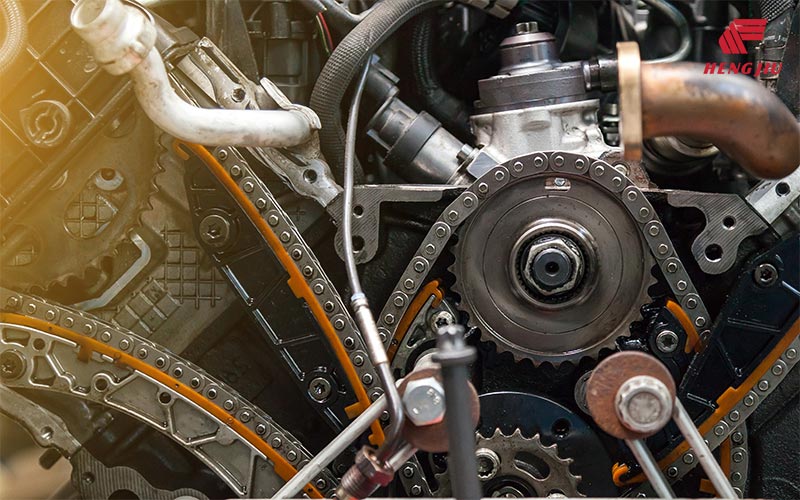

Internal combustion engines use a timing chain to drive the camshaft that last longer as less likely to fail. Today, inverted tooth drive chains are commonly used in passenger car. The chain are used in high-speed high-temperature, and alternating load conditions for long periods. High tensile strength and excellent fatigue and wear resistance are the basic requirements of this chain.

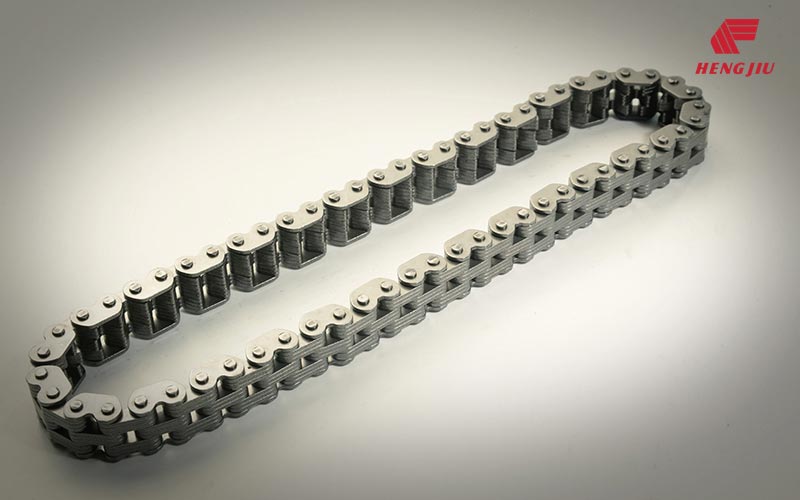

Hengjiu Corporation offers a full range of timing chains, including sleeve chains, roller chains and toothed chains, and timing chains and oil pump chains for American, Japanese and German models. Products are also exported to Europe, America, Southeast Asia and the Middle East.

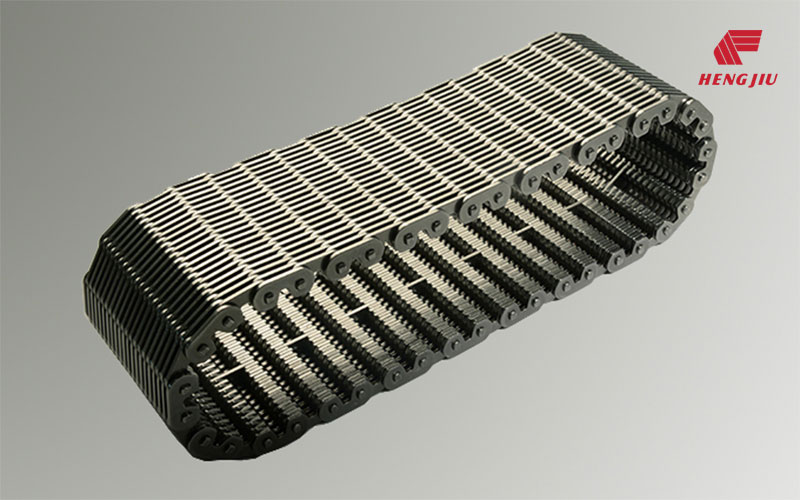

We use high-quality alloy steel in manufacturing our toothed chain parts; chain plate parts are formed by precision extrusion process and isothermal quenching process to attain high degree of hardness, strength and impact toughness. The surface of the pin is super-hardened and achieved great anti-wear performance. Base on chain meshing theory calculation and repetitive verifications and corrections, perfect sprocket teeth and sprocket wheel combination, not only meeting the required strength and reliability, adaptable to the long periods of high speed operation and light weight, but also attain superior noise under such high speed operation.

For conditions that require extremely high wear performance, we can offer a double pin configuration toothed chain. This is a major innovative chain product of ours. The relative rotation between the chain links is changed from the sliding friction structure between the pin and the chain plate to the pin. The anti-wear performance of rolling friction between shafts is several times more than that of the traditional single pin structure toothed chain.